I bought my Ender 5 Plus a little over 5 months ago and can say that I’ve spent enough hours with it to give it an honest review. I’ll start with general thoughts and then go through some of the good and bad observations from the last few months.

In general

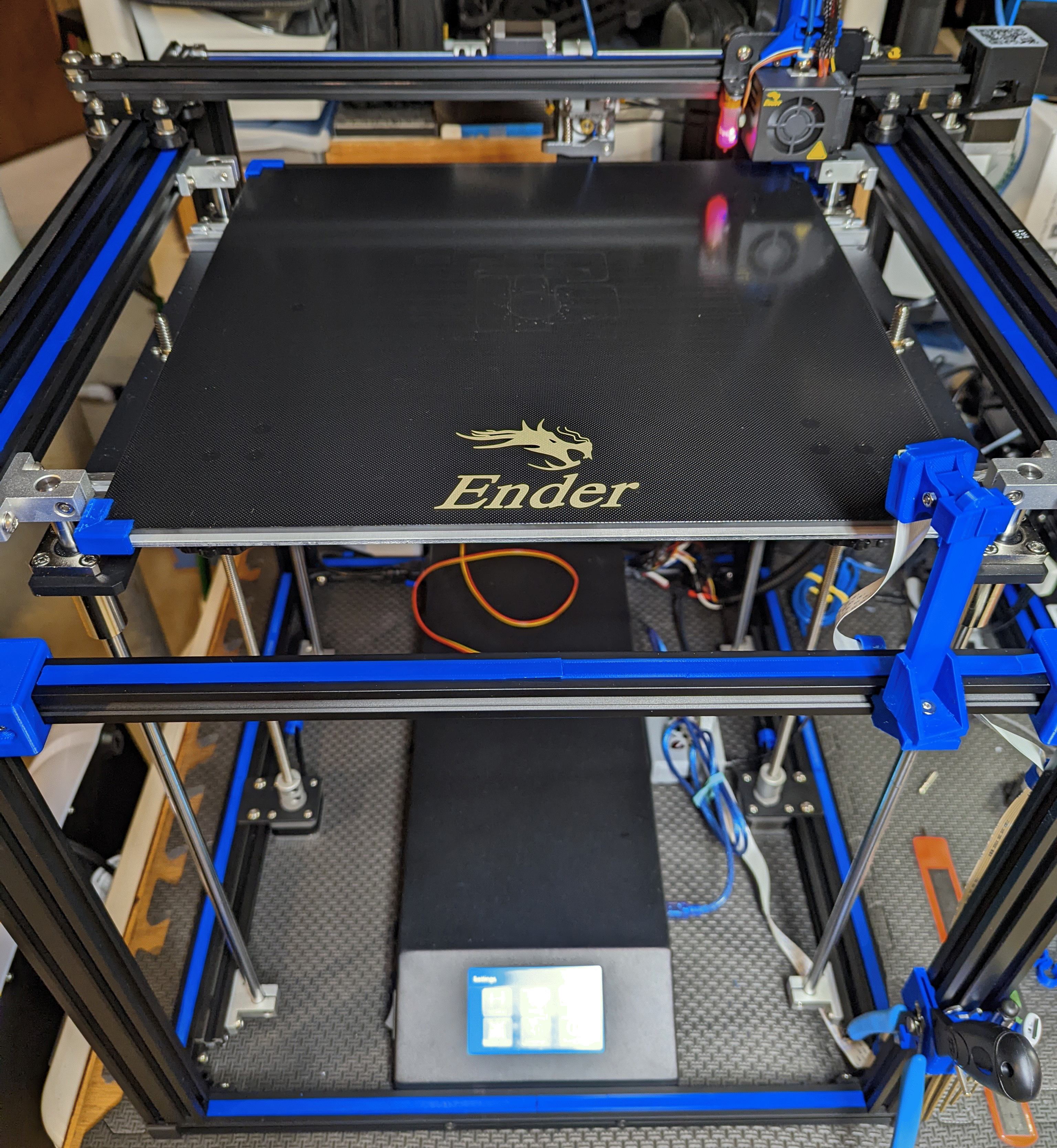

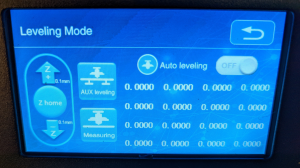

It’s GREAT to have the larger build plate. The LCD screen is easy to read and the menu with a touch screen is intuitive and has most of the features that I need for maintenance and printing. There are a few mods that can be done on the printer (and I’ll list what I’ve done), but I found that it prints great right out of the box. Leveling is really easy, once you are familiar with the steps and some nuances, but it takes a while. Fortunately, I’ve only needed to relevel the printer a few times after hundreds of hours of printing.

The bad and the ugly

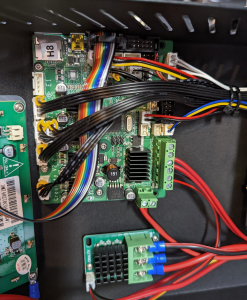

Now let’s get into the cons and general annoyances that I’ve found, starting with the volume (as in sound). No way to sugar coat it, this is a loud printer. I installed the silent motherboard and that helped a lot when printing. However, just sitting there, the fans are the loudest thing in a room including a humidifier and 3 other printers. I’m sure that there are some quieter fans that can be installed in the chassis, but with the factory fan, don’t expect to sleep in the same room as the printer.

For some reason, bed adhesion is not the best. I have a Ender 3 Pro with the Ender PEI glass plate and have never had any issues. There must be a slight difference with the one that was included with the Ender 5 as I’ve found that if I don’t spray alcohol and wipe with a lint free cloth after every print, more often than not part of my first layer will become a free-floating string following the extruder around the plate.

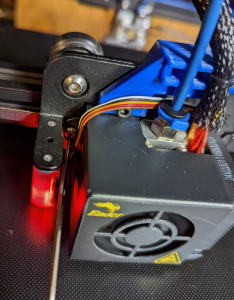

Maintenance sucks. Cleaning out a clog, changing out the nozzle or anything around the extruder is a royal pain. The auto touch leveling sensor is held on with the same bolt as the fan and disassembly can become tedious as you thread the needle trying to screw and unscrew bolts while precariously holding things in place. Even loading and unloading filament can be a chore with the filament end sensor.

Speaking of the filament end sensor, mine stopped working after the first time I changed the filament. If I could get the little blue light to turn on at all while loading the filament (most of the time it wouldn’t), then part way through my print, it would hiccup and send my OctoPrint device into a tailspin. I removed it from the printer and have never looked back since. I’m usually a little paranoid on making sure that I have enough filament before I start something, so having the sensor wasn’t something that was adding a lot of value for me.

I’m extremely grateful for the inclusion of firmware that can detect thermal runaway. I really don’t want a printer to turn into a slag heap that ignites my basement. However, I’ve noticed that my Ender 5 Plus shuts down and sends the ‘Danger Will Robinson’ code to OctoPrint at least once every couple of weeks. So far, unplugging everything from the printer and restarting it clears it up. Still, it’s a little concerning.

The good

As I mentioned, the larger build plate is really the big selling point on the printer. Throw in the auto touch leveling and an easy to use LCD menu and it’s become my main go-to for general printing.

My Maker Select Plus is still by far the fastest printer I own but nothing is better for printing taller prints like the Ender 5 Plus. Without the worry of a moving printing surface to shake loose tall items, I’ve been able to easily crank out things 350mm in height with no issue, even using the stock z-axis lead screw.

That doesn’t seem like many pros, but overall, I’m very pleased with the printer. A lot of things just work and the accuracy is great for a mid-level printer.

The mods

I did some test prints both before and after installing the silent motherboard and it really does make quite the difference in the noise level while actively printing. When printing side by side with my Ender 3 Pro, the smaller printer sounds like a drone trying to achieve ludicrous speed.

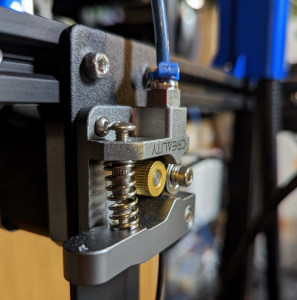

After a few hours of printing and changing out some filament, I did install a metal extruder. The plastic one that came with the printer was working fine but I felt like I was going to snap it in two every time I changed filament.

There are a lot of really knowledgeable people out there that swear by Capricorn teflon tubing. I’ve had to change the expensive tubing out fairly regularly, so the jury is still out on the uplift for me personally.

I was a little concerned that, over time, wires would short or just snap out of the hot end and heated bed, so I printed pieces to mount and tie things down for a little piece of mind.

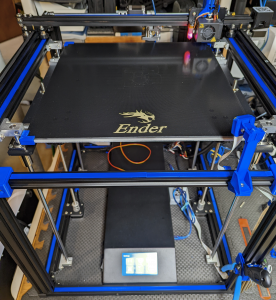

Cable management is a nightmare with this printer. I’ve seen some pretty elaborate mods to manage cables but I found that these simple clips snap into the frame easily and keep things clean and out of the way.

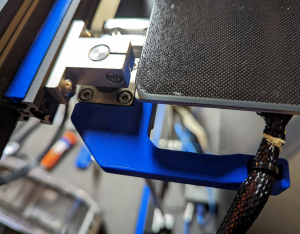

I kind of like the contrast with blue and black. No improvement to printing or maintenance in any way, but I did succumb to the geek in me and printed these track covers. Personally I think the blue gives the printer a Tron sort-of look.

I use OctoPrint on all of my FDM printers and it took a bit to find a camera holder that fit well for my taste. To help with the camera view and to make it a bit easier to get to the prints, I also lowered the front rail.

Well, that’s it for now. Hopefully in another 6 months I’ll still love the printer and Creality won’t decide that they are done supporting it in hopes that everyone will toss their old Ender 5 Plus for the next, slightly improved but with a cool new name, mid-level $500+ printer.